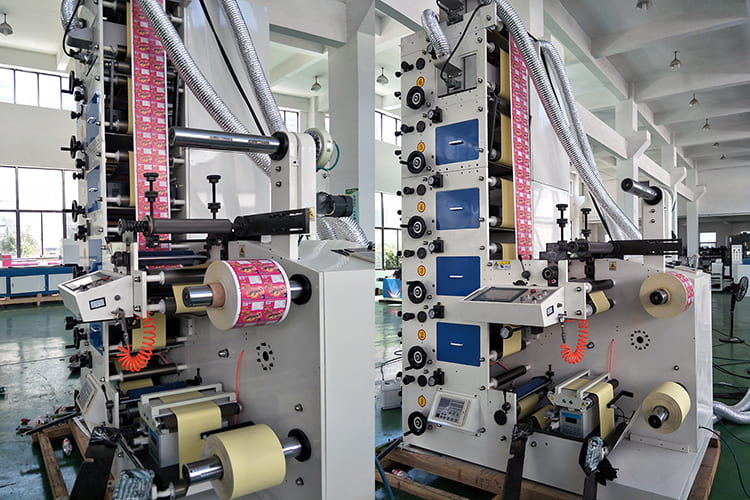

Flexography is a popular printing technique that is widely used in various industries, including packaging, labeling, and publishing. It is a versatile and cost-effective printing method that can produce high-quality prints on a wide range of materials. However, the success of flexography largely depends on the type of material used. In this article, we will explore the different materials used in flexography and their properties.

- Plates

The first and most important material used in flexography is the plate. The plate is the carrier of the image that is transferred onto the substrate. The most common materials used for flexographic plates are photopolymer and rubber. Photopolymer plates are made of a photosensitive material that hardens when exposed to UV light. They are durable, easy to use, and can produce high-quality prints. Rubber plates, on the other hand, are made of natural or synthetic rubber and are ideal for printing on rough surfaces.

- Inks

Inks are another crucial material used in flexography. Flexographic inks are specially formulated to adhere to a wide range of substrates, including paper, plastic, and metal. They are available in different types, such as water-based, solvent-based, and UV-curable inks. Water-based inks are eco-friendly and easy to clean, while solvent-based inks are more durable and resistant to fading. UV-curable inks are cured by exposure to UV light and are ideal for printing on non-porous surfaces.

- Substrates

The substrate is the material onto which the image is printed. Flexography can print on a wide range of substrates, including paper, plastic, metal, and fabric. The choice of substrate depends on the application and the desired outcome. For example, paper substrates are ideal for printing labels and packaging, while plastic substrates are suitable for printing on flexible packaging and bags.

- Anilox Rollers

Anilox rollers are used to transfer ink from the ink fountain to the plate. They are made of a hard, smooth surface that is engraved with tiny cells. The size and shape of the cells determine the amount of ink that is transferred to the plate. Anilox rollers are available in different materials, such as ceramic, chrome, and stainless steel. Ceramic anilox rollers are the most popular due to their durability and consistent ink transfer.

In conclusion, the success of flexography largely depends on the materials used. The right combination of plates, inks, substrates, and anilox rollers can produce high-quality prints that meet the requirements of various industries. As the demand for eco-friendly and sustainable printing solutions increases, the use of biodegradable and recyclable materials in flexography is also on the rise. With the right materials and techniques, flexography can continue to be a cost-effective and versatile printing method for years to come.

+ There are no comments

Add yours